Considering all the pandemic-driven changes, I was adamant about teaching my favorite 7th-grade lesson, Clay Creature Coin Keepers. Hybrid schedules, PPE, or nontraditional individualized supplies never impeded my students’ determination or imagination. Gavin E. constructed his never-before-seen-creature, “Bowling Ball Man.” Prior to glazing, he shared a reference photo of his bowling ball. My initial thought was “All those swirls! All those colors. How do you recreate that with glaze?” I could have responded to my student “oh, we can’t do that.” Instead, I said “Wow, That’s an awesome pattern! Um, creating that with a brush might be difficult. Let me think about it.” What followed was my greatest artistic “What If?” brought to fruition!

I choose to invest in Stroke & Coat by Mayco because it mimics the properties of paint. Its highly pigmented formula is applied with a brush, colors match expected color outcome, intermixability for new hues, and are stable like an underglaze with the shine of glaze. Amidst a winter pandemic shutdown, I daydreamed for days on how to glaze bowling ball swirls. “What if we use the acrylic paint pour cup method with Stroke and Coat?!”

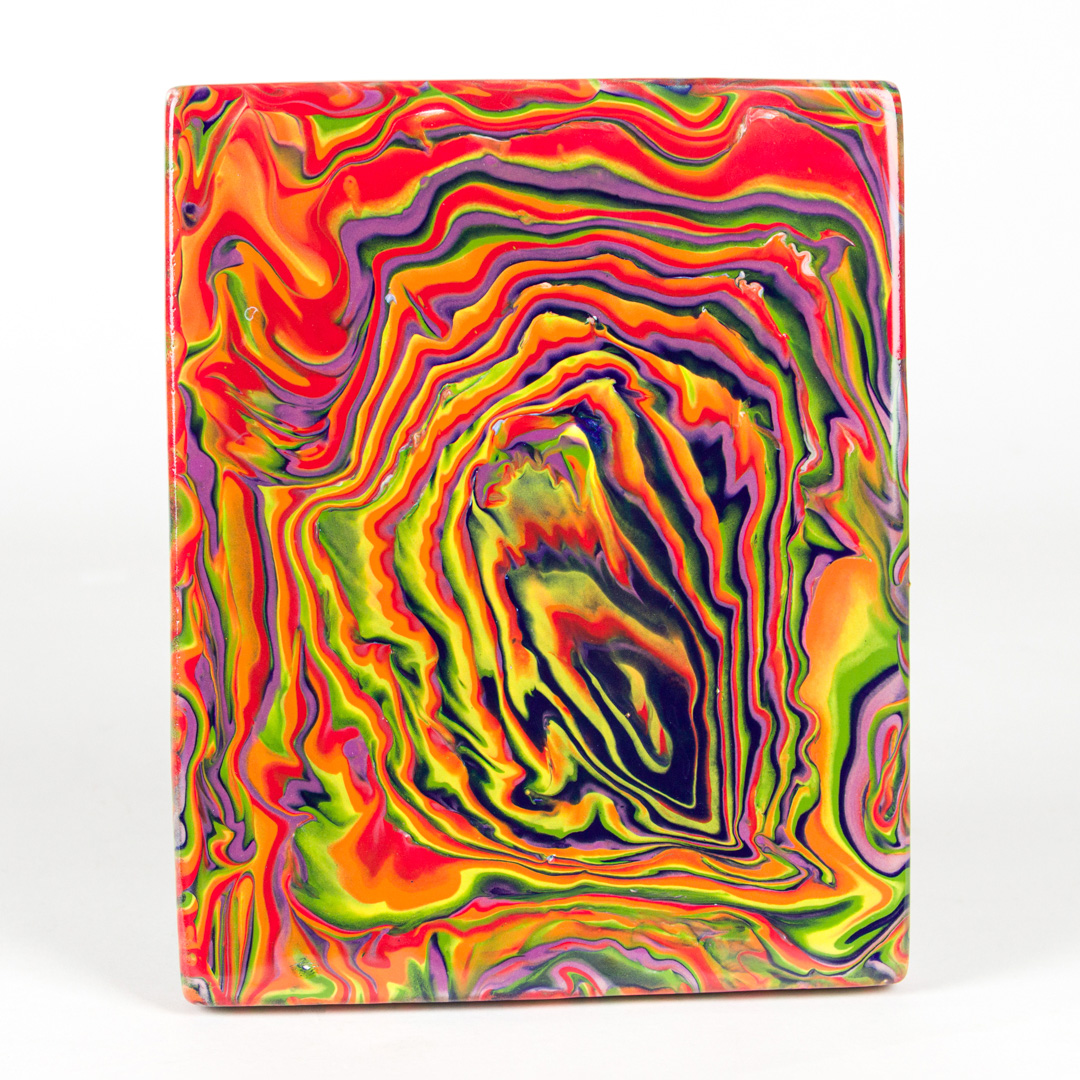

Upon returning I asked Gavin “Are you willing to try something?” Eagerly, a base layer of glaze was brushed on his bisque. Using a recycled condiment cup, he layered Hot Tamale, Orange-A-Peel, and Sunkissed glaze. I demonstrated pouring a small stream of tri-colored glaze on the surface of his ceramics. Even with difficult areas to reach, he wished to fire the outcome (cone 06). Opening the kiln lid revealed trust, honesty, scientific curiosity, and artistic creativity covering his sculpture. Vibrant combinations of fire-like swirls sparked many more “What ifs?”

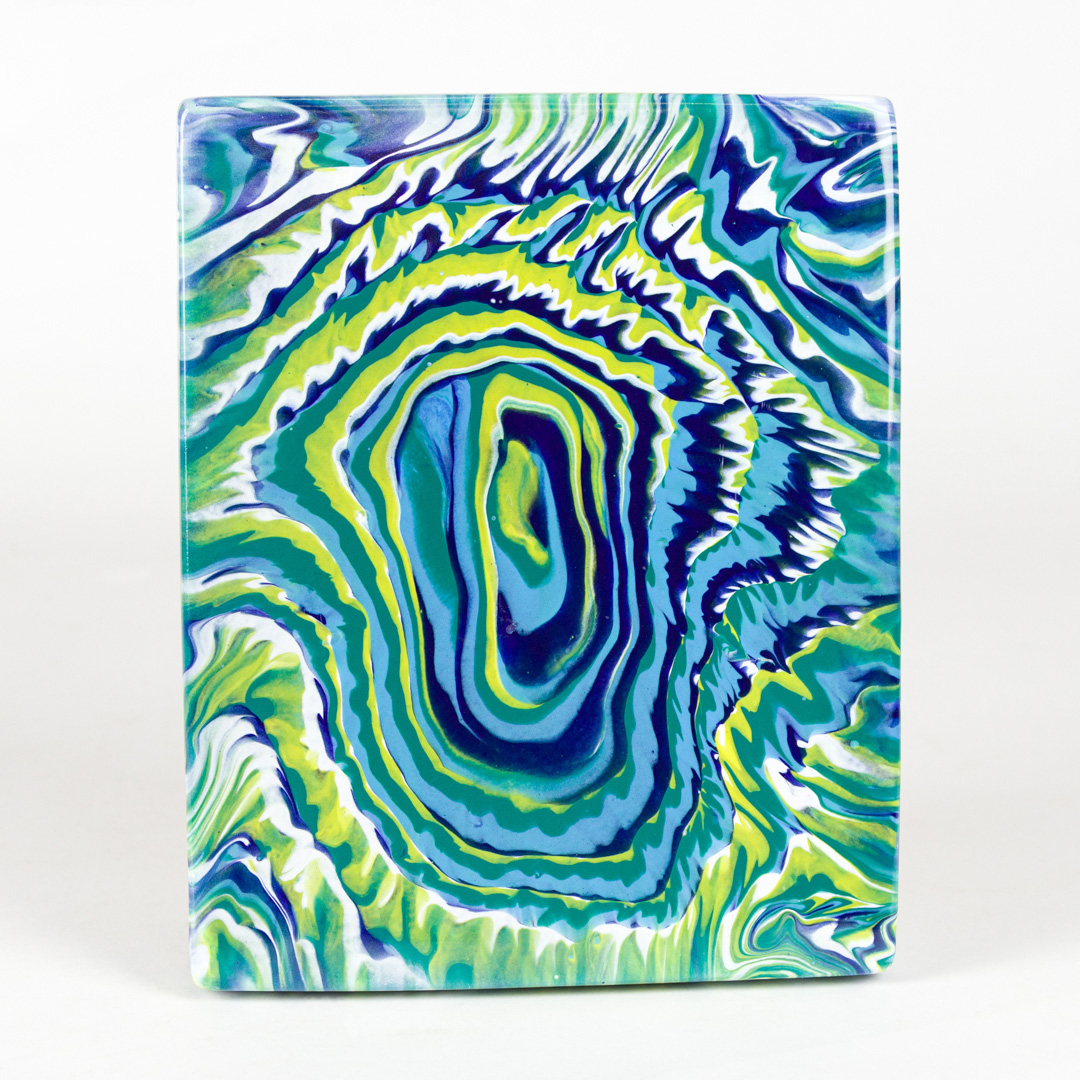

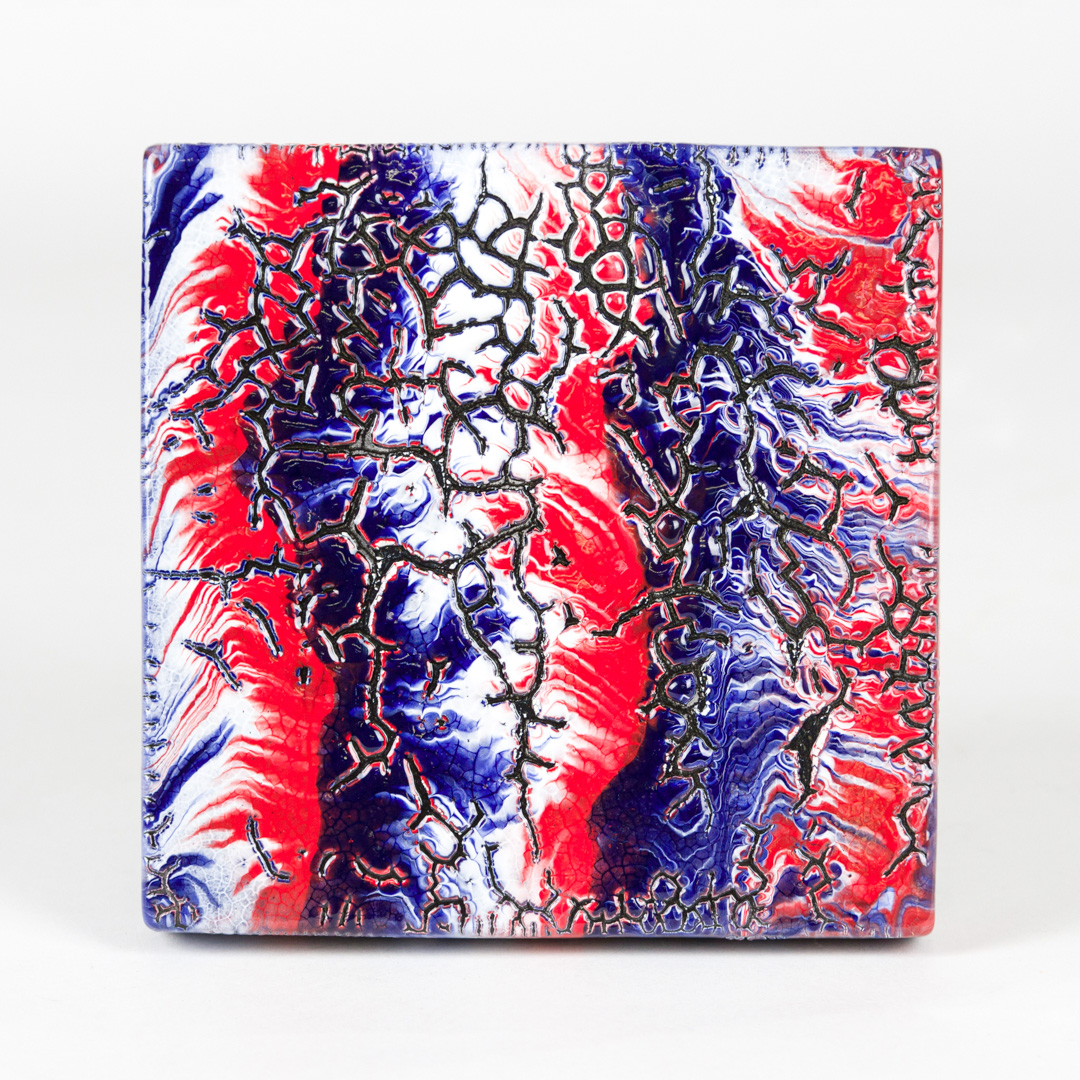

My next apprentice was a former student, 8th grader William B., who requested to make art with me every Wednesday during the pandemic. William’s artistic excellence frequently inspired my personal exploration with the method. Every extra moment was filled with scientific artistic experiments with glaze viscosities, methods of application, and clay bodies. Discovering Mayco’s Clay Canvases facilitated further testing “The Wonderglaze’s” ability to mimic the unique pour painting properties which can’t be obtained by a brush. The local ESC bestowed Ohio Art Council grant funds, supporting our experimentation as I enacted professional development workshops for this method.

After extensive research including all 198 lessons of Mayco’s lessons, I emailed headquarters and packed up Gavin’s, William’s and my Glaze Pour artworks still pondering “What if?” On April 30th, 2021, Mayco’s CEO/President confirmed controlling multiple colors poured in a single stream that does not become “muddy” is a NEW way of applying the glaze. Mayco desired my lesson plan, testing of other glaze formulas, and filming my demonstrations of the method. I am thrilled to share all the variations tested and the unique elements to Glaze Pour Paintings that in my opinion surpass their predecessors.

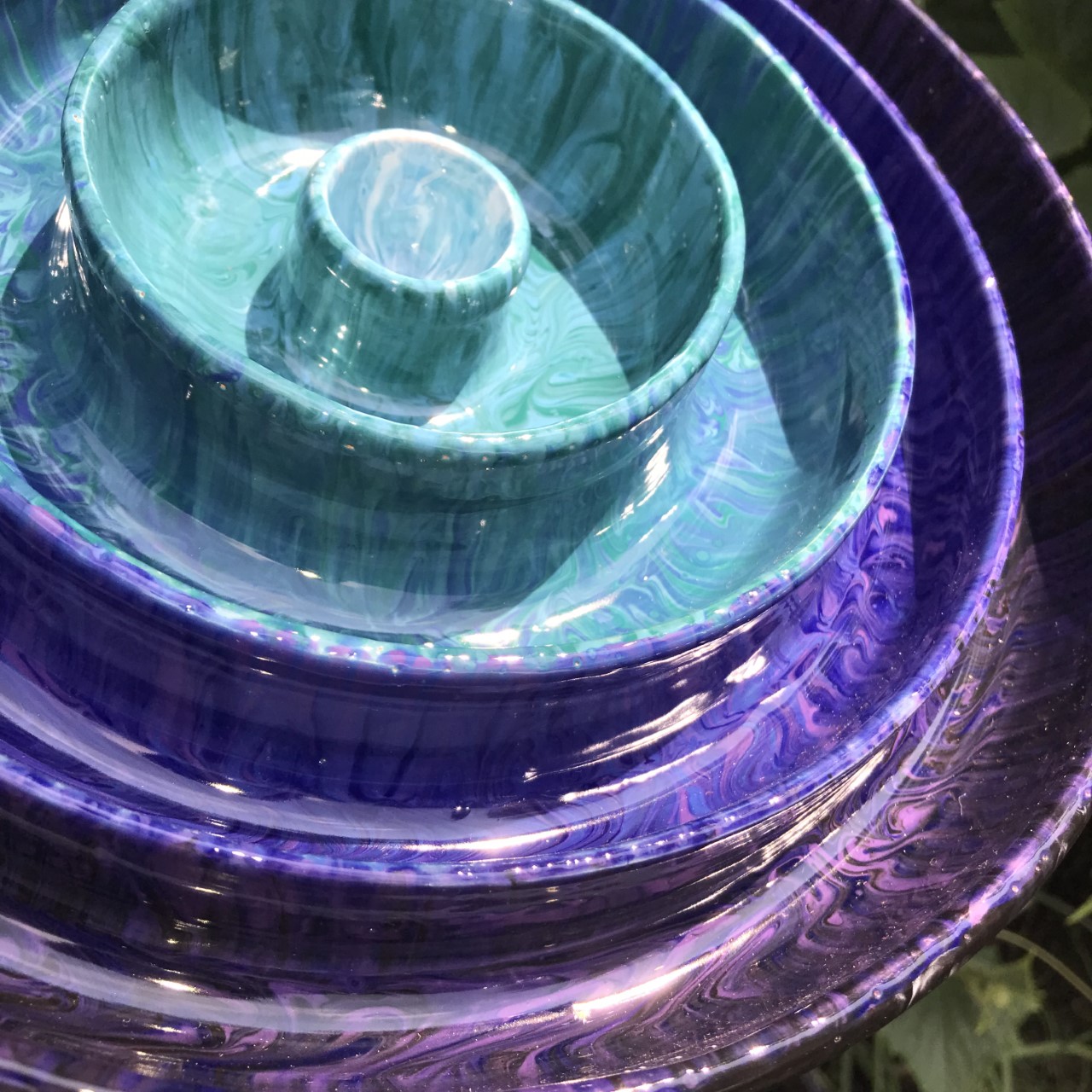

Why teach Glaze Pour Painting? Aesthetically, results are vibrant including remarkable intermixing, shine, depth & permanence. Academically, there is minimal waste due to the porous surface and interdisciplinary concepts are taught concurrently. Connections include the chemical reaction of the glazing process, viscosity, and what earthen materials melt to make glaze’s colorful waterproof surface that was a huge social/technological advancement. Stroke & Coat is very densely pigmented which can be thinned up to 15% with water for desired effects and increases supply for the classroom. Expand the process by incorporating wax resists, stencils, or other specialty glazes like Sculpting Medium or Cobblestone also alter the glaze path across the surface with replicable yet endless results. Glaze Pouring on greenware eliminates extra time-consuming kiln firings. Gassing off during this once-fired process will create temporary bubbles through glaze that produce the look of paint/silicone “cells.” In mid-range firings, Stroke & Coat produces true Reds that do not “burn out” (cone 6). Foundations glazes are more economical and do not need to be thinned but translucency does necessitate smart color theory to avoid neutral tones. Glaze Pour Painting absolutely works on functional or sculptural pieces with masking tape, brushes, silicone cups, and a misting bottle conquering most obstacles.

My willingness to honor a student’s desire, not dismissing it because I couldn’t see the solution created a surreal journey of “What Ifs”? answered by perpetual momentum. In less than 6 months, I developed this method, taught this method on 6” tiles to my 7th graders/art educators, and proposed numerous workshops. Mayco filmed my instructional videos for Glaze Pour Paintings and I remained stunned by commissions received and artworks sold. You and your students’ unexpected “What If” moments are waiting if you are brave enough to do what we ask of our students…TRY!