Mayco’s Stoneware glaze assortment, including Classic, Matte, Crystal, and Gloss, offers a variety of finishes, textures and endless possibilities for glaze combinations. Available in both liquid and dry.

Cone 6 chips have been fired flat in oxidation on white stoneware body.

Cone 10 chips have been fired flat in reduction on white stoneware body.

One of the most distinctive traits of Mayco’s Stoneware is that the glazes provide consistent performance and intriguing visual interest. They are best known for being receptive and favorable to the user during both application and firing. Mayco Stoneware glazes are friendly to the user in application, layering and firing. Many glazes will break over textures, revealing secondary colors and shades. The choice of clay body, thickness of glaze application, firing process and temperature will affect the fired results.

Mayco Stoneware glazes offer the depth, sophistication and reliability to artists working from mid-range to high-fire temperatures.

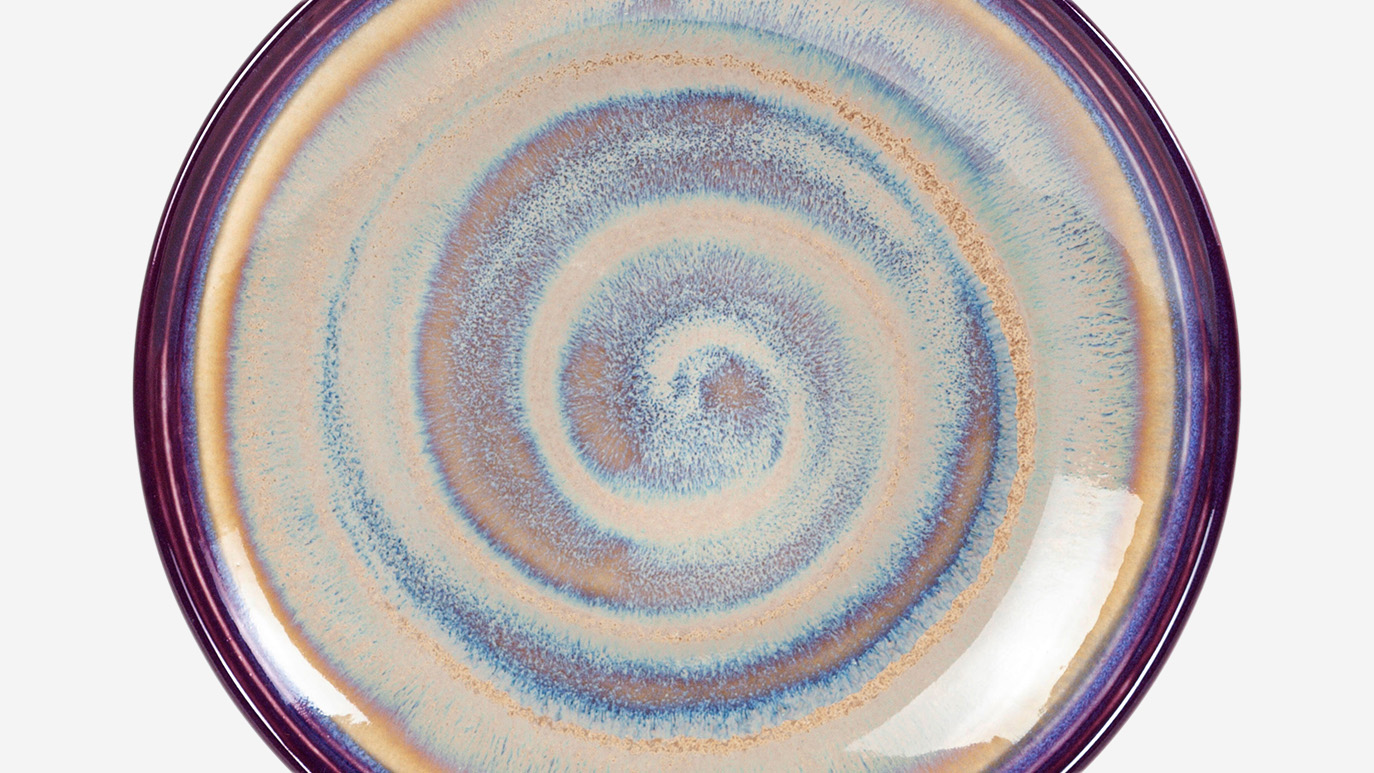

Mayco’s Stoneware Classic glazes satisfy a variety of performance and color selections that range from bright and vibrant to earthy and subdued. Our Stoneware glazes provide a variety of finishes, movement, and variation. Some glazes are high gloss, opaque, and flat in color, while others have a more complex surface that is varied in both finish and color. The Stoneware Classic glazes also include Opals and Ice (translucent) glazes. These glazes heighten surface details where they gather and pool, work well on a variety of clay bodies and have a firing range from cone 5-10.

Choose from solid shades to those that create interesting color variation as they move and break. Our Stoneware Matte glazes provide a variety of colors and performance characteristics. Some matte glazes have opaque solid coverage and others are semi-transparent and variegated. Application thickness is key to making Stoneware Matte glazes work for you. Mattes work well on a variety of clay bodies and have a firing range from cone 5-10.

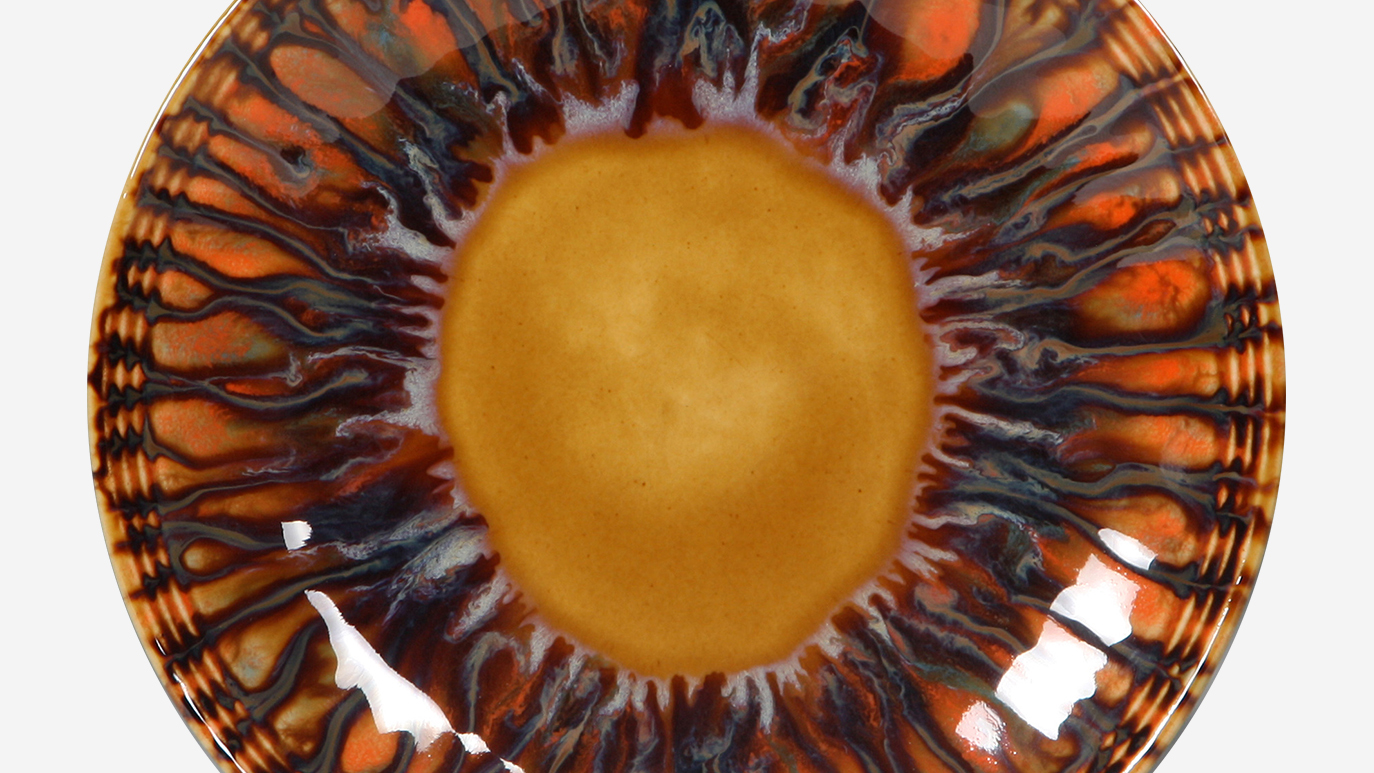

Mayco’s Stoneware Crystal glazes are a unique line of glazes that contain colorful crystals in the glazes themselves that are designed to melt and bloom during the firing. These crystals add variation in color, finish, and movement to the glazes that you already know and love! All of our Stoneware Crystal glazes begin with a base glaze; most of the base glazes can be found in our other Stoneware Glaze lines. You can find the information about the base glazes of all our Stoneware Crystal glazes on the label, in the description on our website, or click here to download the Excel file.

Mayco’s Stoneware Gloss glazes produce bright, opaque colors with a high gloss finish. Stoneware Gloss glazes can be used in design, all over coverage and are the ideal product for intermixability at mid-range temperatures. The integrity of your design will remain unchanged as these glazes are incredibly stable and will not move or combine with surrounding colors. As with all of our Stoneware Glazes, our Gloss glazes work well on a variety of clay bodies and have a firing range from cone 5 to cone 10, some colors change slightly at higher temperatures.

Select Mayco’s Stoneware glazes are available in both liquid pint and dry glazes in increments of 10 lbs. Dry formulas are added to water and used in buckets for dipping or pouring techniques. Many functional potters prefer dipping to painting for even coverage. The colors and formulas are identical in dry form, minus the added organic gums. Mayco Stoneware Dry glazes (SD is the prefix, it stands for Stoneware Dry) are great for pieces with a lot of surface texture and for layering techniques. See videos at the bottom of this page for more information.

Stoneware Classic & Matte Glazes: Stir well. Apply to soft-fired bisque (cone 04/06). Apply one, two or three coats depending on the result desired. Allow each coat to dry before applying the next coat. Fire from cone 5/6-10. See label for additional firing information for individual glazes and cone 10 performance.

Stoneware Gloss Glazes: Stoneware Gloss glazes can be used in design, all over coverage and are the ideal product for intermixability at mid-range temperatures. The integrity of your design will remain unchanged as these glazes are incredibly stable and will not move or combine with surrounding colors. See label for additional firing information for individual glazes and cone 10 performance.

Dry mix products: Always wear a NIOSH-approved respirator when handling dry glazes. Gently tumble unopened bag to redistribute material, Sieving is not necessary. Mix one 10Ib bag of Dry material into at least 10 pints of water. Stir thoroughly. Add additional water until desired Specific Gravity is reached. Specific Gravity preference will vary between studios, persons, and practice. Our recommended Specific Gravity is in the range of 1.47-1.51. This is for a 1 second dip time; you may want to mix to a lower Specific Gravity if you layer your glazes or tend to dip longer. Stir well before each use. We suggest using dipping tongs. Immerse the ware for 1-2 seconds. One dip of Mayco Dry is equivalent to 3 coats. Shake excess glaze off gently. Allow the glaze to dry before applying additional coats, if desired. When applying Stoneware Dry Crystal glazes, use a cup or ladle to pour the glaze over your piece. While the glaze is wet, you may use a fan brush to evenly distnbute the crystals; avoid heavy crystal loading on the bottom 1/3 of your piece. Fire to preferred temperature, cones 5-10 (2167°F-2345°F / 1186°C-1285°C). Testing recommended. The choice of clay body, the thickness of glaze application, the firing process, and temperature will affect the fired results.

Tip: Save your bag or log the lot number for if you have any questions for our technical team. Tip: Apply AC-302 Wax Resist to the bottom for easy dry foot clean-up.

Mayco Stoneware Classic glazes are a mixture of AP Non-Toxic and CL (Health Caution) label. Please review the individual color label for health classification and any appropriate warnings. All but one (see below) of the Stoneware glazes in the Classic line are Food Safe, according to FDA standards. Note: Finishedware producers may be required to have their ware food safe tested prior to introducing into commerce. With the exception of those noted below, The Stoneware Classic and Matte glazes are also Dinnerware Safe when used according to manufacturer’s directions and fired to the clay body’s vitrification temperatures. SW-132 Mirror Black, SW-182 Antique Brass, SW-164 Satin Patina, SW-185 Rainforest, SW-186 Azurite, SW-187 Himalayan Salt, SW-188 Landslide, SW-195 Riptide, and SW-197 Fossil Rock are not Dinnerware Safe due to the durability of the fired glaze. Some glazes, regardless of surface texture or porosity of underlying clay body, will be designated as not suitable for dinnerware as the fired glaze surface is not durable and can be impacted by contact with food or liquids. While it may not be harmful, it is certainly not desirable. SW-132 Mirror Black, SW-182 Antique Brass, SW-164 Satin Patina, SW-185 Rainforest, SW-186 Azurite, SW-187 Himalayan Salt, SW-188 Landslide, SW-195 Riptide, and SW-197 Fossil Rock are recommended for ornamental use only.

Mayco Stoneware Crystal glazes are a mixture of AP Non-Toxic and CL (Health Caution) label. Please review the label for the individual color’s health classification and any appropriate warnings. All of the glazes in the Crystal line are Food Safe, according to FDA standards. Note: Finishedware producers may be required to have their ware food safe tested prior to introducing into commerce. The Stoneware Crystal glazes are also Dinnerware Safe when used according to manufacturer’s directions and fired to the clay body’s vitrification temperatures. However, discretion and judgment should be used if the glaze surface is heavily textured, less from a safety and more from an aesthetic perspective.

Mayco Stoneware Gloss glazes are AP Non-Toxic, Food Safe, and Dinnerware Safe, when used according to manufacturer’s directions. Note: Finishedware producers may be required to have their ware food safe tested prior to introducing into commerce.

Mayco Stoneware glazes work great layered both under or over other glazes. Artists can achieve incredible finishes with a simple combination of two glazes

Used alone, Mayco Stoneware glazes produce beautiful color variations, deepening with additional coats. One coat will allow more of the clay body to show through the glaze. Subsequent coats deepen the color. Gloss Glazes are the ideal product for brightly colored dinnerware.

Use Mayco Stoneware Dry glazes (SDs) for fast dipping and layering, creating natural flowing effects. Fine and uniform particle size and a thorough dry mixing process make Mayco Stoneware Dry glaze consistency so perfect that sieving is optional. Available in 10 lbs. bags with volume pricing available. See videos at the bottom of this page.

For fast glazing and flowing effects, we recommend using Mayco’s Stoneware Crystals Dry mix glazes (SDs). Due to the crystals settling to the bottom, we recommend mixing thoroughly and pouring the mixed glazes onto your piece with a pour container or pitcher. Over application in the same area may cause crystals to fall off. Available in 10 lbs. bags with volume pricing available. See videos at the bottom of this page.

Many Stroke & Coat® glazes perform well at mid-range. Darker colors such as red, orange, yellow, blue and green may darken compared to their cone 06 results. Lighter colors such as tan, purple and pink will fade.

Many Elements™ and Elements™ Chunkies create beautiful effects when used with stoneware at mid-range. Elements™ will be quite fluid and move during the firing process so keep away from the bottom of the ware.

Jungle Gems™ glazes perform at midrange for very interesting results. Crystals will have additional movement at higher temperatures and will act more as a blending agent.

Designer Liner enables artists to achieve crisp, non-moving linework from cones 06 – 6 temperatures. To ensure sharpness in line quality, use a non-moving translucent or clear glaze over the top of Designer Liner.

Mayco Stoneware glazes are intended for use at cone 5/6, but many are also pleasing and stable at cone 10 oxidation, reduction or other alternative atmospheric firing conditions, such as wood, salt or raku. Cone 10 color performance can also be found on the left side of the stoneware glaze label. The choice of clay body, thickness of glaze application, firing process and temperature will affect the fired results. Due to variability, we recommend testing prior to application to artwork.

Glazes will perform differently based on clay body used. We recommend testing prior to application to artwork.

Mayco’s Stoneware Gloss glazes are incredibly stable and opaque in design work and for majolica techniques at mid-range temperatures. The integrity of your design will remain unchanged as these glazes will not move or combine with surrounding colors. Lighter colors can be used over darker colors, remaining bright and opaque.

Most Mayco Stoneware glazes will break over textures, revealing secondary colors and shades. These glazes heighten surface details where they gather and pool.

There is a lot of variety with our Stoneware glazes so finding the glazes that work best for you can certainly be intimidating! There are some grouping throughout our Stoneware glaze line that are similar in performance, which can prove helpful when selecting glazes.

Crystals – Our Stoneware Crystal glazes are a unique line of glazes that contain colorful crystals in the glazes themselves that are designed to melt and bloom during the firing. We add glass aggregate to the base glaze, which melts during the glaze firing to create beautiful crystal blooms and color variation.

Mattes – Our Stoneware Matte glazes provide a variety of colors and performance characteristics. Some matte glazes have opaque solid coverage and others are semi-transparent and variegated.

Ice Glazes (SW-201 through SW-212) – These glazes resemble celadons. They provide a variety of transparent colors that work well over design work and texture. Thicker application of these glazes will produce a more saturated color that is still transparent. Pay attention to your brush strokes with these glazes, uneven application will produce variation in the color saturation. To avoid a streaky finish, we recommend applying 3 coats of glaze in a cross-hatching motion. Brush glaze out to a smooth surface to avoid bumps and ridges in the wet glaze. SW-203 Amber Topaz, SW-204 Root Beer, and SW-210 Emerald Green are the only glazes in this line that can produce movement when applied thick. If using any of the 3 over design work, we recommend applying 2 coats to ensure stability. Movement with those 3 glazes will be increased on a vertical surface.

Opals (SW-250 through SW-255) – These glazes are semi-transparent glazes that have variation in color and opacity that is dependent upon application. Thicker applications will result in a more opaque and saturated color that will pool and break over texture. Thinner application will result in a transparent finish. Applying Opals over design can produce movement depending on the application thickness.

Gloss (SW-501 through SW-510) – This line of glazes was developed to produce bright, opaque colors with a high gloss finish. They are perfect for detailed design work or all-over vibrant colors at stoneware temperatures. (Also, check out our Gloss article here…)

Texture (SW-403 through SW-406) – Our Stoneware Texture glazes create a unique and dimensional surface. We offer two different kinds of Stoneware Texture glazes currently, Mudcrack and Magma. Our Mudcrack glazes have a soft matte finish that will pull apart during the firing to reveal the underlying clay body. We have a white and a black Mudcrack available. Our Magma glazes have a dry and cratered finish that expands during the firing to create a textured and dimensional surface. We have a dark and a light Magma available. (Also, check out our texture article here…)

Flux (SW-401 and SW-402) – Our Fluxes are designed as “glaze enhancers”. They were developed to be used in combination with other stoneware glazes to enhance the mobility. Our Fluxes interact with other glazes to create movement, which bring out hidden colors and variation.

Washes (SW-301 through SW-305) – Our washes are highly concentrated oxides that can be used alone or in combination with other glazes. Each wash has its own unique qualities, so we recommend testing on test pieces to get an understanding of their individual performance.

Mayco’s Stoneware Classic and Matte glazes are great for layering with other glazes. There is a large variety in performance amongst these glazes, some that we recommend for their performance and compatibility in combinations are SW-104 Black Walnut, SW-106 Alabaster, SW-108 Green Tea, SW-110 Oyster, SW-128 Cordovan, SW-165 Lavender Mist, SW-166 Norse Blue, SW-167 Sand and Sea, SW-168 Coral Sands, SW-172 Macadamia, SW-173 Amber Quartz, and SW-174 Leather. They work great layered both under or over other glazes. Find some inspiration in our stoneware combination gallery.

Mayco’s Stoneware Crystal glazes are also great for layering with other glazes! The crystals will often pop through with most combinations and really add an extra element of excitement to any combination. Our crystal glazes work great layered both under and over other glazes.

All of our Stoneware Gloss glazes can be layered with other glazes. We recommend applying our Stoneware Gloss glazes as the top glaze in a combination if you want the color to be most visible. Applying it as a base of a combination will not produce any ill effects, but it is likely to get lost underneath another glaze due to the stable nature of the product. These glazes do not add much movement to glaze combinations

We offer both brushing and dipping formulations for all of our Stoneware glazes.

For brushing application: apply 2-3 coats of glaze allowing the glaze to dry in between coats.

For dipping application: Agitate glaze immediately before use. Securely grab the piece with dipping tongs and submerge for 1 full second to achieve the equivalent of 3 coat brushing glaze. Allow the piece to dry before subsequent dips if desired. Mayco’s Stoneware glazes have a variety of performance qualities. For best results we always recommend testing with your preferred clay body and firing temperature. Glazes variation is dependent upon application technique and thickness.

All Mayco’s Stoneware glazes have a firing range from cone 5 to cone 10. No particular firing schedule is necessary to achieve the beautiful variation that these glazes create. All of the samples that we showcase in our promotional material and literature are glazed on a white clay body and fired to cone 6 unless otherwise noted. Expect some variation in the results depending on the glaze thickness, clay body, firing atmosphere, and firing temperature. We have cone 10 reduction results on our website, in our Stoneware Brochure, and listed on the label.

All of Mayco’s Stoneware glazes are both Food Safe when used according to manufacturer’s directions and Dinnerware Safe with the exception of SW-132 Mirror Black, SW-182 Antique Brass, SW-164 Satin Patina, our Stoneware Texture glazes (SW-403 through SW-406), and our Stoneware Washes when used alone (SW-301 through SW-305). There is a factor of personal discretion when considering the use of any glaze on a surface that comes in contact with food. Some factors such as clay body, firing temperature, firing atmosphere, and the layering of glazes also contribute to the suitability of a ware for dinnerware use. It is the responsibility of the customer to practice practical consideration of these factors and observe how they affect the final fired surface. For more information about Food Safe and Dinnerware Safe guidelines check here: https://www.maycocolors.com/resources/dinnerware-food-safety/

Yes the can. Some will change significantly, some not much. Best we can do is provide this visual gallery and let you see what each glaze can do at cone 10 reduction. Cone 10 color performance can also be found on the left side of the stoneware glaze label. The choice of clay body, thickness of glaze application, firing process and temperature will affect the fired results. Due to variability, we recommend testing prior to application to artwork.

The crystals that we mentioned above are actually glass aggregate that create the beautiful crystal blooms and variation in the fired glazes. These crystals are designed to expand upon the surface during the firing. No particular firing schedule is required to produce the dazzling burst of color that the crystals provide.

Knowing the base glaze to any of Mayco’s Stoneware Crystal Glazes is useful information for several reasons. First, it provides some insight as to how the glaze will perform. SW-181 Night Moth for example, the base glaze is SW-508 Black Gloss. Black Gloss is a very stable and opaque glaze, which gives reason to believe that Night Moth will not have much movement and will provide great coverage. Of course, there are multiple factors that contribute to the performance of any glaze, but familiarizing yourself with the base glaze is a great place to start! Another benefit of knowing (and possessing!) the base glaze is the option to control the crystal loading and possibly even extend the life of your glaze. If you have the base glaze in your studio, you can cut in some coats of the base glaze to help lighten the crystal loading if you only want a little variation or are glazing near the bottom of your piece. It also provides a great compliment to be used alongside the crystal glaze. You can find the information about the base glazes of all our Stoneware Crystal glazes on the label, in the description on our website, or click here to download the Excel file.

When you first open a jar of Mayco’s Stoneware Crystal glazes, be sure to agitate the crystal pebbles from the bottom of the jar by stirring. Once you have broken up this glorious mound of magical star dust, replace the lid tightly and give it a good shake to distribute the crystals throughout the entire jar. Then you are good to go! Storing our crystal glazes upside down can help keep the crystals near the top of the jar, but no matter how you store your glaze, be sure to give it a good shake before each use.

We offer both brushing and dipping formulations for all of our Stoneware Crystal glazes.

For brushing application: apply 2-3 coats of glaze allowing the glaze to dry in between coats.

For dipping application: Agitate glaze immediately before use. Be sure to adequately disperse crystals throughout the glaze and immediately pour the glaze over the ware using a ladle or cup.

While glaze is still wet, use a brush to help evenly disperse the crystals. Be aware of the crystal loading and dispersion on all of your pieces. Heavy concentrations of crystals can create movement in the glaze. Avoid having a heavy concentration of crystals near to bottom of your piece to ensure successful results.

As with all of Mayco’s Stoneware glazes, they have a firing range from cone 5 to cone 10. No particular firing schedule is necessary to achieve the beautiful variation that these glazes create. The samples we showcase in our promotional material and literature are glazed on a white clay body and fired to cone 6 unless otherwise noted. Expect some variation in the results depending on the glaze thickness, clay body, firing atmosphere, and firing temperature. We have cone 10 reduction results on our website, in our Stoneware Brochure, and listed on the label.

These glazes are 100% intermixable and perfect for shading and blending. Looking for a grey? Mix one-part SW-508 to three-parts SW-501 and there you have it, a perfect grey for all your shading needs. If you can do with paint, you can do it with Mayco’s Gloss glazes! Using teaspoons of color is a good way to experiment with different ratios of color without wasting glaze. Once you have found the color you want, you can always up the size to tablespoons, ounces, cups or 5lb bags of dry color. Enjoy exploring the endless colors you can create with this palette of ten simple glazes.

Our manufacturing process includes ball milling to very precise particles sizes. All you need to do to use our dry-mix glazes is add water, slake, stir and DIP. You’ll love the sheeting action when dipping and be pleased to find that our dry-mix glazes will not settle out in your storage bucket.